Drones in Construction: How Aerial Robotics Could Revolutionize Building Practices

In a bold leap toward the future of construction, researchers from Imperial College London and the University of Bristol have unveiled a groundbreaking vision: aerial robots building structures in mid-air. Their study, recently published in Science Robotics, explores how Aerial Additive Manufacturing (Aerial AM) could transform the safety, sustainability, and scalability of the global construction industry.

Building Without Boundaries

Traditional construction is constrained by the ground—workers, cranes, and ground-based robots can only reach so far. Aerial robots, however, operate within an unrestricted work envelope, soaring over terrains and scaling heights previously deemed inaccessible or hazardous. This newfound freedom promises to unlock construction possibilities in remote, difficult, or dangerous environments where conventional methods fall short.

Moreover, these aerial systems could minimize environmental impacts. By using advanced material deposition techniques, drones can potentially reduce construction waste, lower energy consumption, and improve the overall sustainability profile of large-scale projects.

What is Aerial Additive Manufacturing?

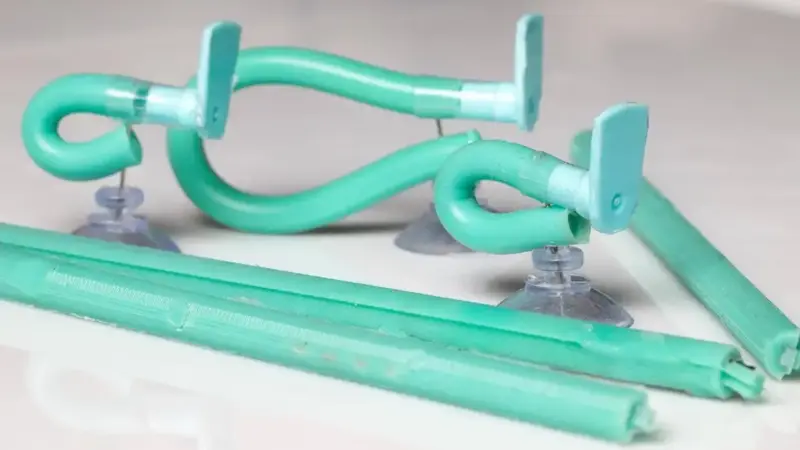

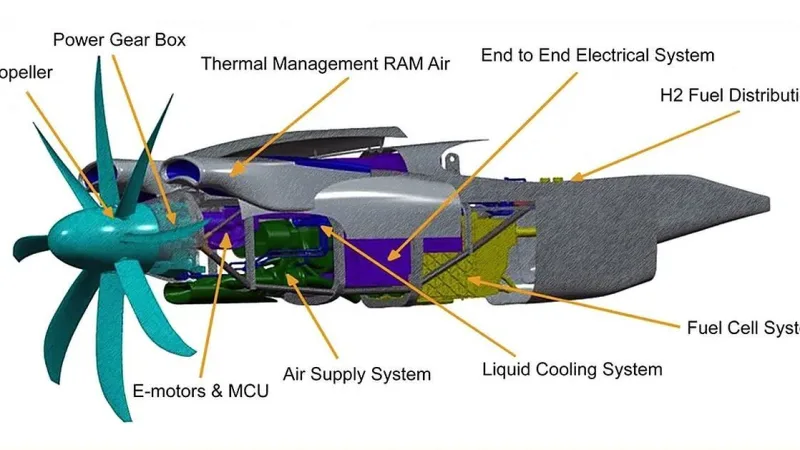

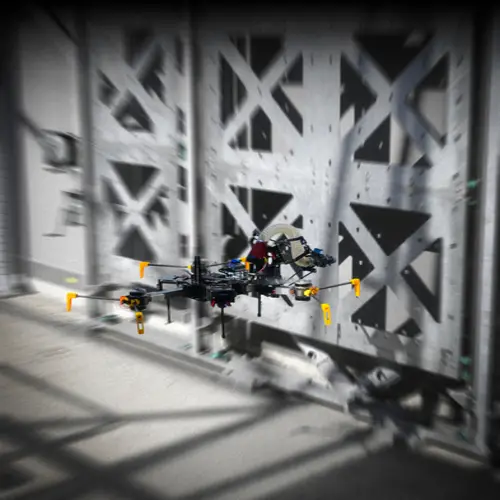

Aerial AM is essentially an airborne version of 3D printing. Drones, outfitted with precision manipulators and material dispensers, deposit construction materials layer-by-layer, shaping structures mid-flight. While early prototypes have focused on simpler tasks like on-demand repairs and modular assemblies, the vision is to scale this technology for full-fledged construction projects.

Challenges

Despite its promise, the field of Aerial AM remains in its infancy. As Dr. Basaran Bahadir Kocer from the University of Bristol’s School of Civil, Aerospace and Design Engineering notes, several hurdles must be overcome:

- Material Durability: The materials used must harden quickly yet remain strong enough to support the structure under varying environmental conditions.

- Outdoor Localisation Systems: Accurate navigation in uncontrolled, outdoor environments remains a significant technological challenge. GPS alone may not offer the precision required.

- Fleet Coordination: Large-scale projects would require swarms of drones working simultaneously, which introduces complex challenges in real-time coordination, collision avoidance, and task delegation.

Addressing these technical bottlenecks is critical for transitioning from controlled laboratory demonstrations to practical, real-world applications.

Testing the Skies

To move beyond theoretical models, researchers are now testing these systems in real-world environments. At DroneHub, based at Switzerland’s EMPA (Swiss Federal Laboratories for Materials Science and Technology), Aerial AM technologies are being trialed outside the laboratory for the first time. This platform offers researchers an invaluable opportunity to fine-tune drone performance under authentic conditions.

This initiative is further supported by a thriving collaboration between the University of Bristol and EMPA, strengthened by fully-funded PhD studentships and access to cutting-edge facilities like Bristol’s Flight Lab, Bristol Robotics Laboratory, and the Aerial Robotics Group.

Why It Matters

The implications of this research stretch far beyond traditional building sites. Imagine drones rapidly constructing temporary shelters in disaster-stricken areas, repairing critical infrastructure in inaccessible locations, or even assembling structures in extraterrestrial environments like the Moon or Mars.

By integrating aerial robotics into construction, we’re looking at a future where building is faster, safer, greener.

Source:

Research Paper Referenced: “Aerial Additive Manufacturing: Towards On-site Building Construction with Aerial Robots“

Authors: Yusuf Furkan Kaya, Lachlan Orr, Basaran Bahadir Kocer, Vijay Pawar, Robert Stuart-Smith, and Mirko Kovac

Published in: Science Robotics