Lessons in Structural Engineering from the Tragedy of 9/11

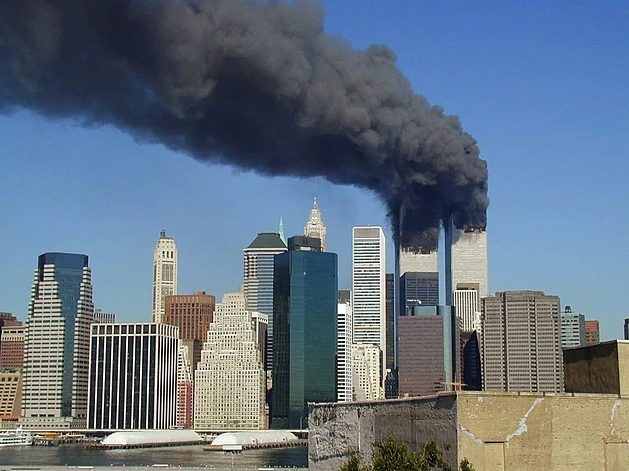

The devastating events of 9/11 had a profound impact globally. The unthinkable act of violence that occurred on that day changed our perception of safety and security. As we witnessed the collapse of the World Trade Center towers, questions arose about how such a catastrophe could happen. These were not only natural queries born out of grief, but also inquiries from the perspective of structural engineers. They asked, amidst the destruction, how did the towers manage to stay standing even for a brief period of time?

The Resilience of Twin Towers’ Structural Elements

Considering the extensive damage inflicted by the commercial aircraft crashes, it is surprising how the twin towers did not immediately collapse. When the towers were designed, the possibility of an accidental airplane collision was a concern. However, the events of 9/11 went beyond anyone’s expectations. The impact caused instant destruction of crucial structural elements, in addition to starting large fires across multiple floors while the sprinkler systems failed. Despite these challenging conditions, the towers remained standing due to their redundant mechanisms for weight support.

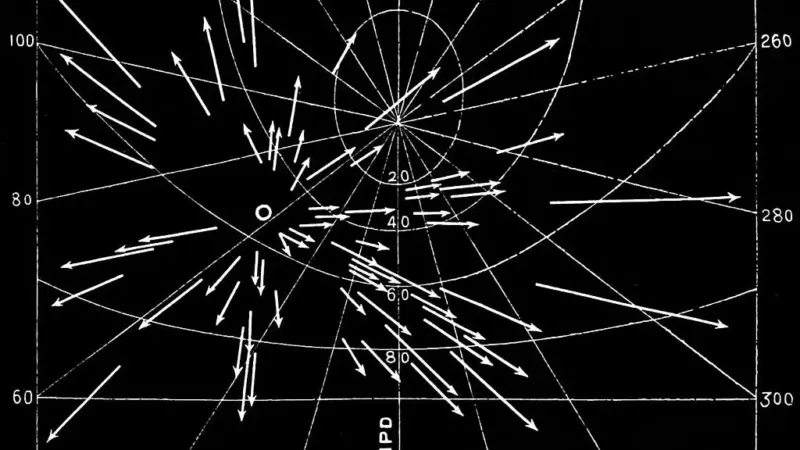

The exterior walls of the towers were distinct, with narrow windows and closely spaced steel columns. Deep beams at the floor levels created a lattice-like structure covering the surface of the buildings. The construction involved off-site welding, where panels of the lattice, three stories tall and three columns wide, were fabricated and then transported to downtown Manhattan. These panels were vertically staggered to increase durability, ensuring that their tops and bottoms did not align at the same floor level. The four sides of each building formed a tube that carried the weight of the structure directly downward to the foundations. The walls acted as wide and tall vertical beams that could bend to absorb wind loads.

When the aircraft sheared columns and beams in the exterior walls, the latticework above the damage served as horizontal beams, spanning several stories to bridge the gap. Simultaneously, the damaged walls were partially suspended from the structure above. The strength of the closely spaced structural elements allowed the walls to sag without collapsing completely. In this compromised state, the towers provided valuable time for occupants to evacuate from below the collision floors and surrounding buildings.

The Pentagon: Another Example of Structural Resilience

Eventually, the intense fires within the towers weakened the floor systems that braced the exterior walls. As the walls buckled, the upper portions of the buildings fell, demolishing the lower floors as they descended. Similarly, the Pentagon endured an airplane crash on 9/11. Less well-known is the fact that a portion of the damaged area stood for approximately 20 minutes before collapsing. Despite the plane crashing into its first floor and demolishing numerous columns, the Pentagon held up long enough for upper-level occupants to evacuate.

The Pentagon’s steel-reinforced concrete structure relied on a two-way floor system, with beams connecting columns in both directions for added support. When the columns were destroyed, the building above sagged, but the crisscrossed floor beams acted as a safety net to uphold the damaged area. The concrete columns themselves had embedded vertical steel bars that worked in conjunction with the concrete to bear the weight. Horizontal steel bars wrapped around and braced the vertical bars, confining the concrete within. In line with construction practices of the 1940s when the Pentagon was built, the horizontal steel bars were spiraled, providing ductility that allowed for sharp deformation without rupture. The tightly confined concrete columns maintained their position despite bending, curving outwards up to three times the diameter of the vertical steel bars. Even with significant damage, many columns still carried weight, minimizing the area that required the floor to act as a net.

The collapsed portion of the Pentagon was far smaller than the area initially undercut by the airplane crash. Just like the towers, the collapse resulted from intense fires further weakening critical structural elements.

Lessons for the Structural Engineering Profession

In response to incidents like those on 9/11, the structural engineering profession continually strives to improve safety and resilience. Organizations such as the Structural Engineering Institute at the American Society of Civil Engineers, the National Institute of Standards and Technology, and the Federal Emergency Management Agency conduct studies to enhance building practices. These investigations have highlighted the importance of characteristics like redundancy and ductility in withstanding extreme assaults. Building upon this knowledge, researchers and practicing engineers aim to create structures that are both safe and economically viable, even in the face of damage.

Preventing “disproportionate collapse,” where widespread collapse follows localized damage, is a significant concern. The goal is to prevent cascading collapse from events as small as a fire, explosion, or a vehicular impact. After the bombing of the Alfred P. Murrah Federal Building in 1995, new guidelines were issued to resist explosions. The fires that ultimately led to the collapse of the World Trade Center and the Pentagon emphasized the need for better analysis of fire effects on buildings. SEI/ASCE will soon release guidance on mitigating the risk of disproportionate collapse. To promote knowledge sharing, SEI/ASCE has established the Collaborative Reporting for Safer Structures U.S., a platform allowing engineers to exchange lessons learned from failures.

Like everyone, structural engineers mourn the losses of 9/11 and fear the potential for future catastrophic failures. However, they are not complacent in the face of failures. Continuing to study, learn, and improve is their mission.

(Opinion and analysis article by Donald Dusenberry, a consulting engineer and former president of the Structural Engineering Institute at the American Society of Civil Engineers)